Molding process

Overmolding is an injection molding process in which a connector, a printed circuit board or a component is placed into a mold to be encapsulated by a thermoplastic mantle or layer. In our production we use low pressure and high pressure overmolding:

Low pressure overmolding

Low pressure overmolding works with low viscosity materials (like polyamide or polyolefin). Ideal for overmolding sensitive parts like printed circuit boards.

High pressure overmolding

High pressure overmolding allows the use of higher viscosity materials like polyurethane.

Benefits

Overmolding ensures the proper functioning of your product or device because it protects against intrusion of dust and water and also against vibration and mechanical stress. Low pressure molding is a more reliable and efficient method than potting or using protection housings.

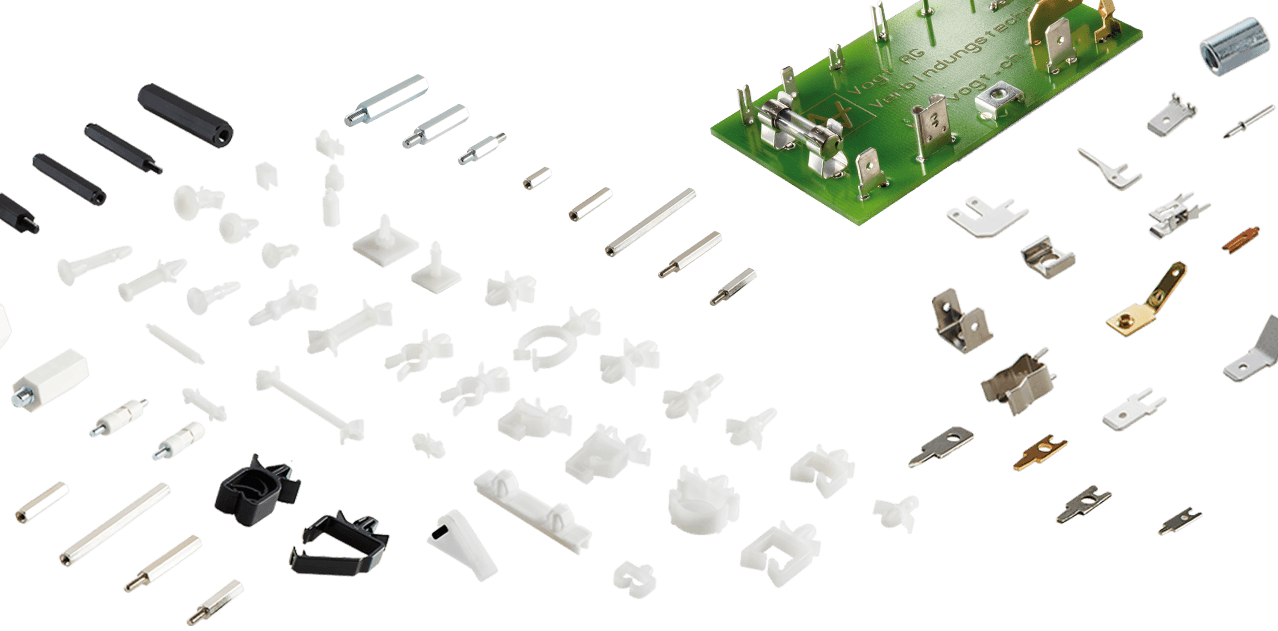

Molding tools

Cost effective aluminium tools are used for low pressure molding, allowing even the production of small series.

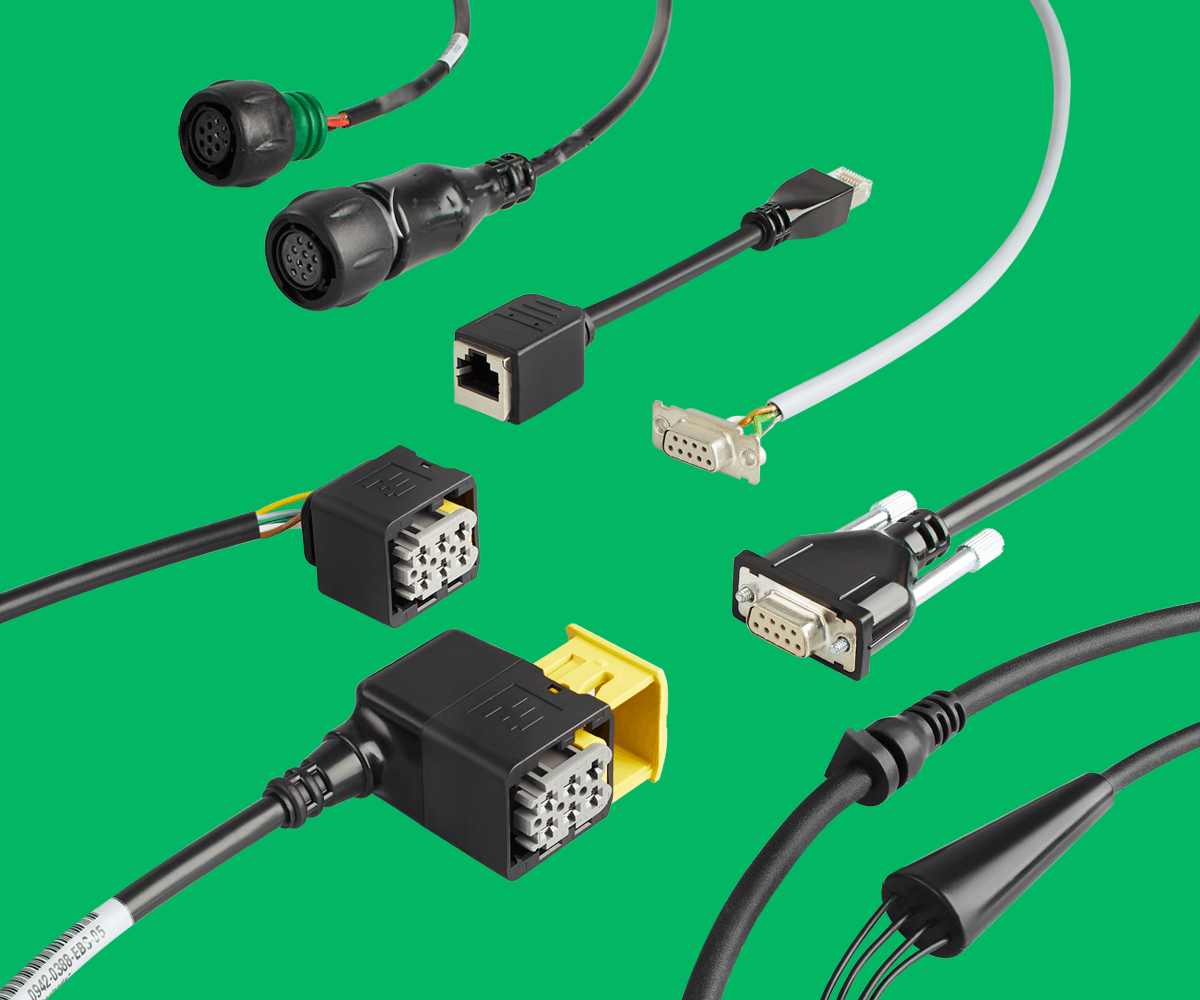

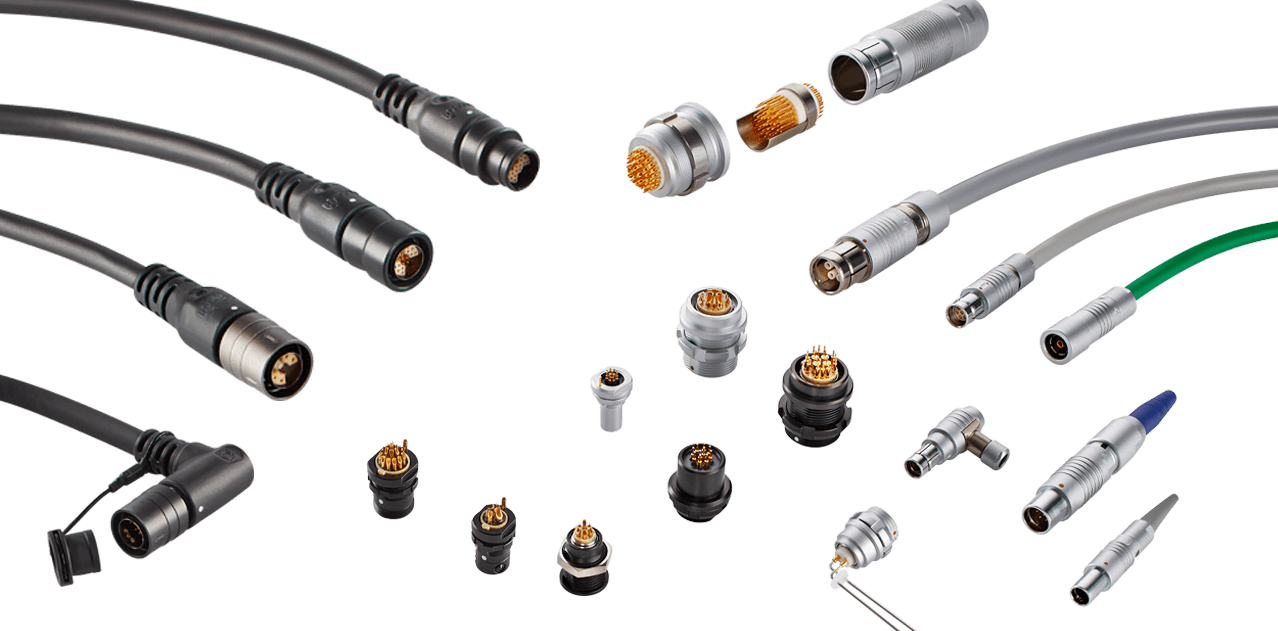

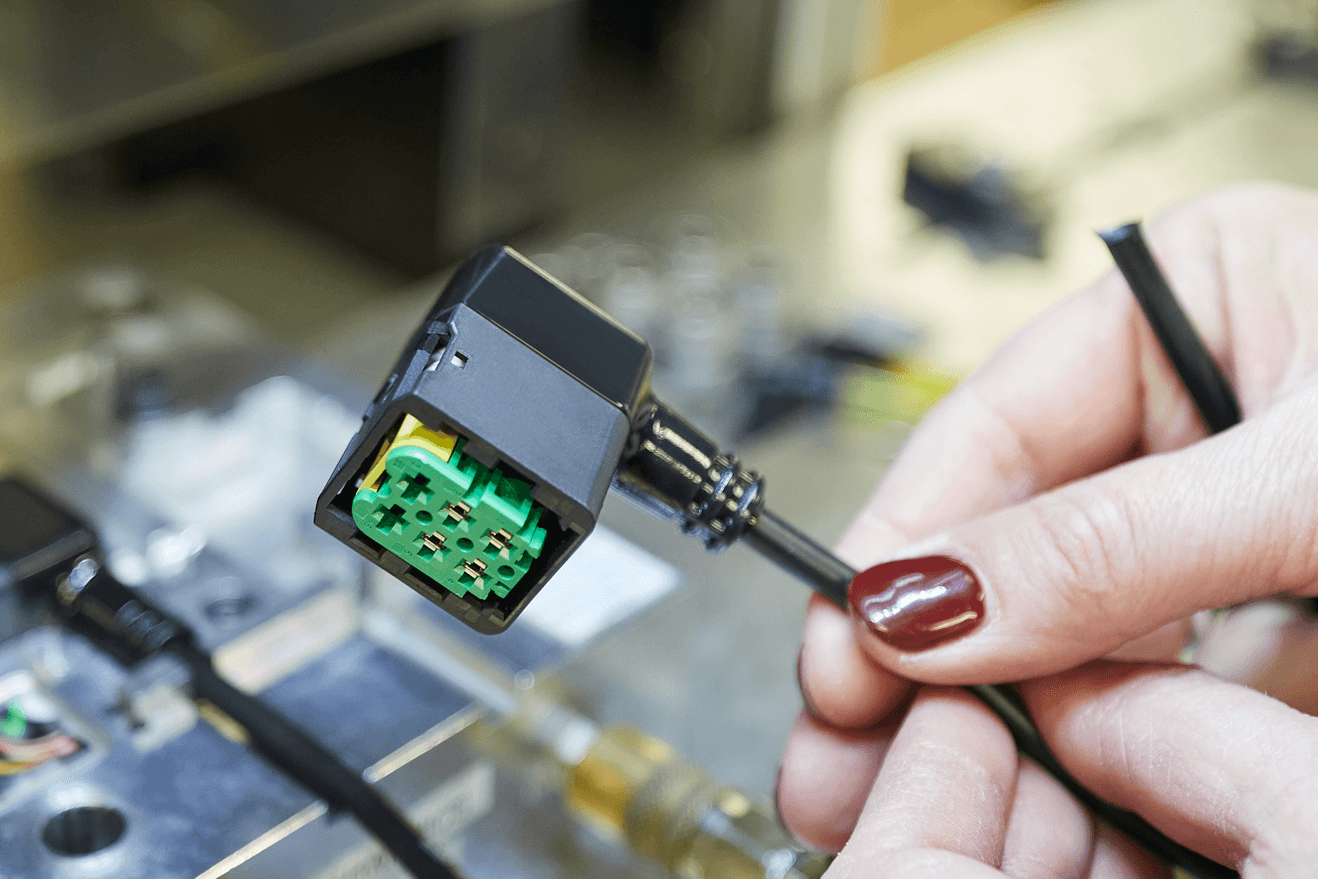

Overmolded circular connectors

Cabled circular connectors overmolded with polyurethane ensure the proper functioning of your device, because overmolding protects against the intrusion of dust and water into the connection. It offers strain relief and protection against vibration, bending forces and mechanical stress. Ideal for medical equipment, instrumentation, sensor configurations, the pharmaceutical and food industry.

A very wide range of connector solutions

For more robust applications (like marine, heavy industrial or defense) polyurethane delivers a tough yet flexible overmolding, extending the lifetime of cable assemblies in rough environments.

For medical purposes cabled connectors can be overmolded with friction-free, flexible and sterilisable silicone.

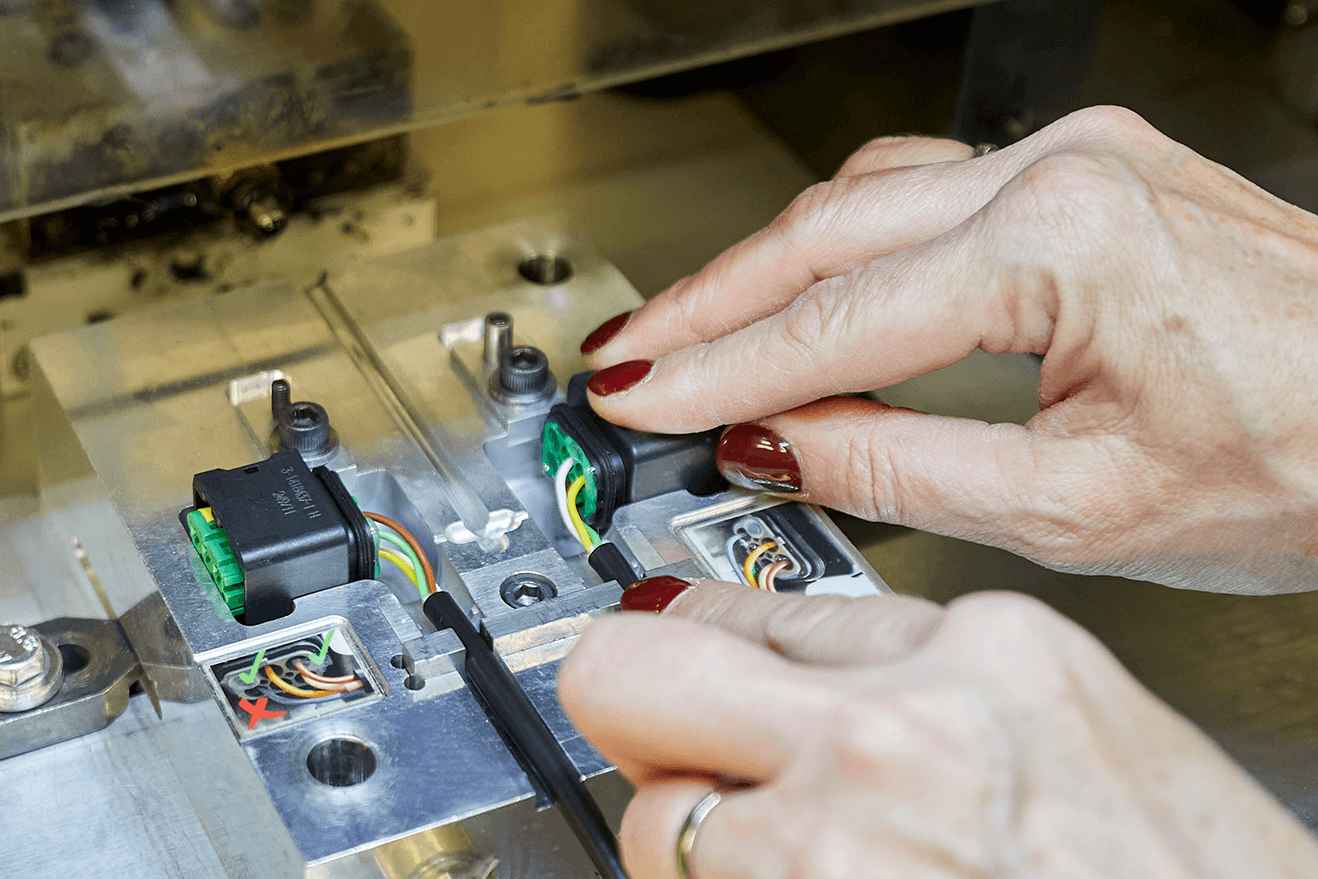

Floating overmolding by clamping on external connectors

This is an example of a printed circuit board that we have overmolded with Technomelt® low pressure molding material from Henkel. By clamping the PCB on its connectors we can make sure that the PCB is overmolded 360º in every direction. This ensures that there are no open gaps through which dust, moisture or water could ingress.

360º overmolding by using integrated support posts

By using three support posts we can make sure that the PCB is overmolded 360º in every direction.

This ensures that there are no open gaps through which dust or water could ingress.

Overmolding with high and low pressure