Quality control integrated into the production process

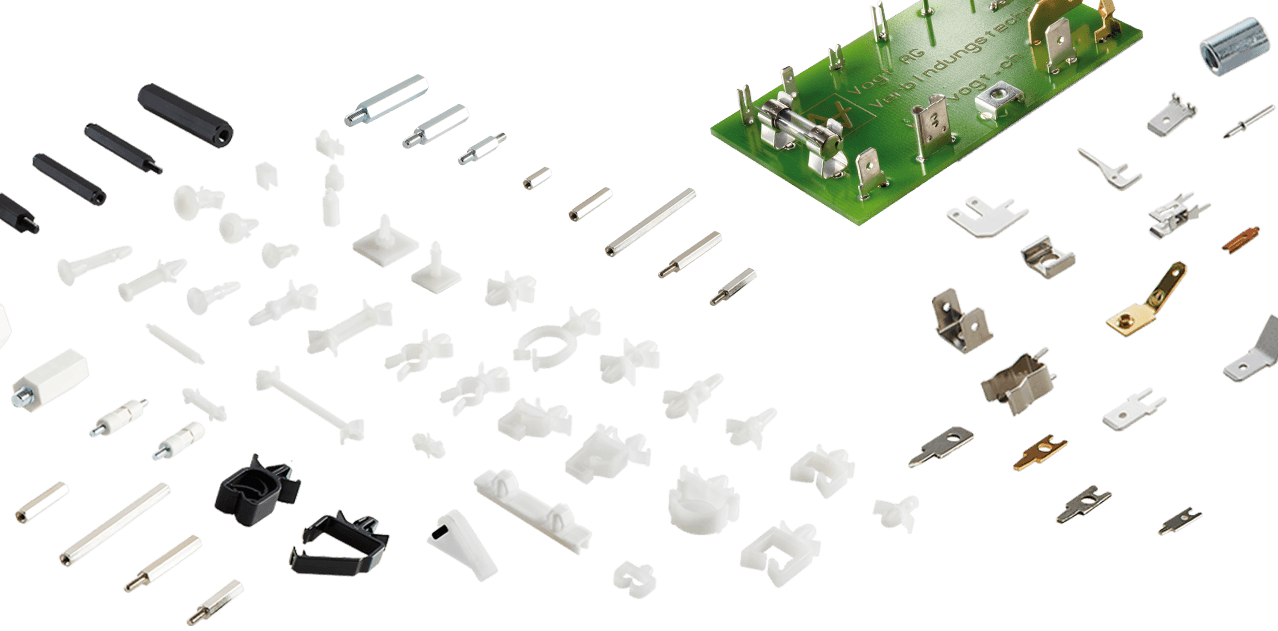

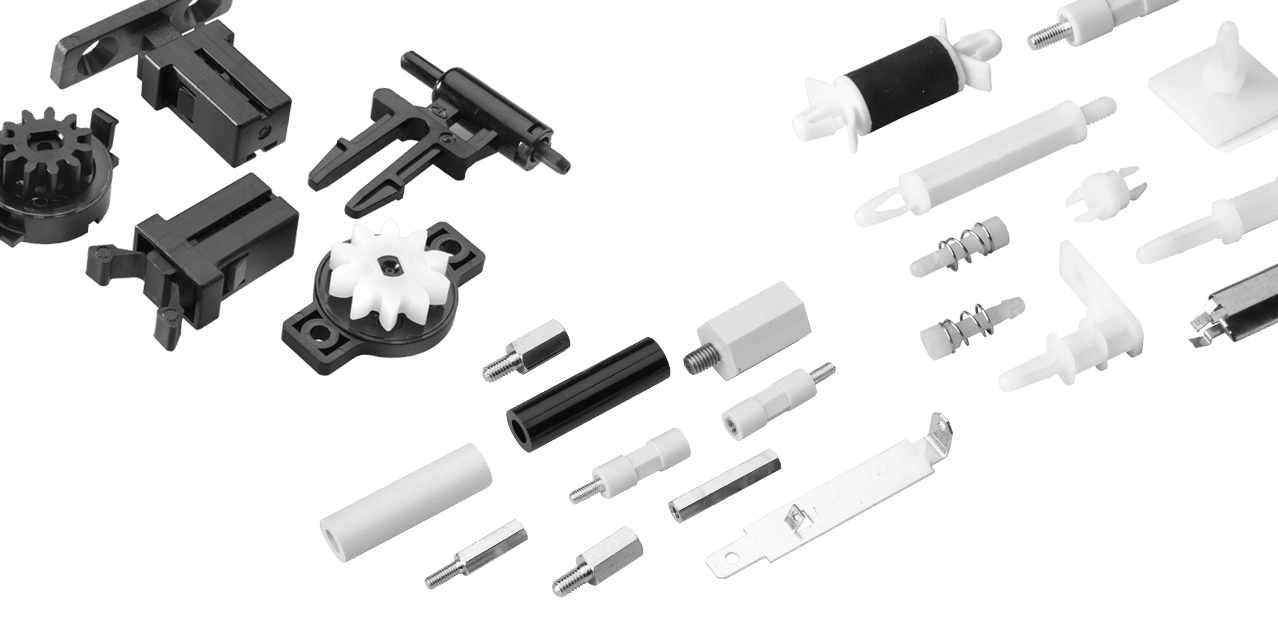

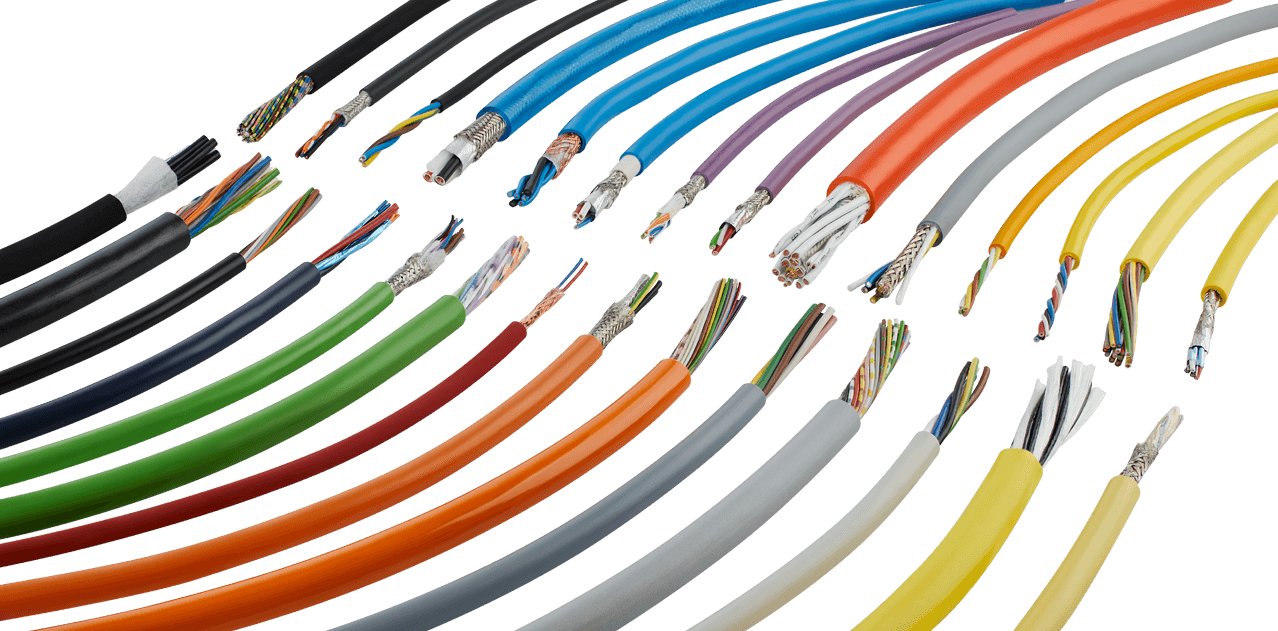

Our fully automatic Komax wire processing machines combine high output with integrated quality control of the crimped terminals. Crimp terminals transmit power and signals and thus serve as the nervous system of your product. Reliability and durability are vital requirements. During the crimping cycle the wires can also be marked with clear, indelible inkjet printing. In addition to our fully-automatic machines, we have special machines and equipment for:

- Cutting and stripping extremely small wire gauge as small as AWG 30 (0.05 mm2)

- Cutting, jacket stripping and coiling heavy cables up to 90 mm2 in one cycle

- Three-stage stripping of coax cable in a single cycle with an accuracy of up to 0.01 mm

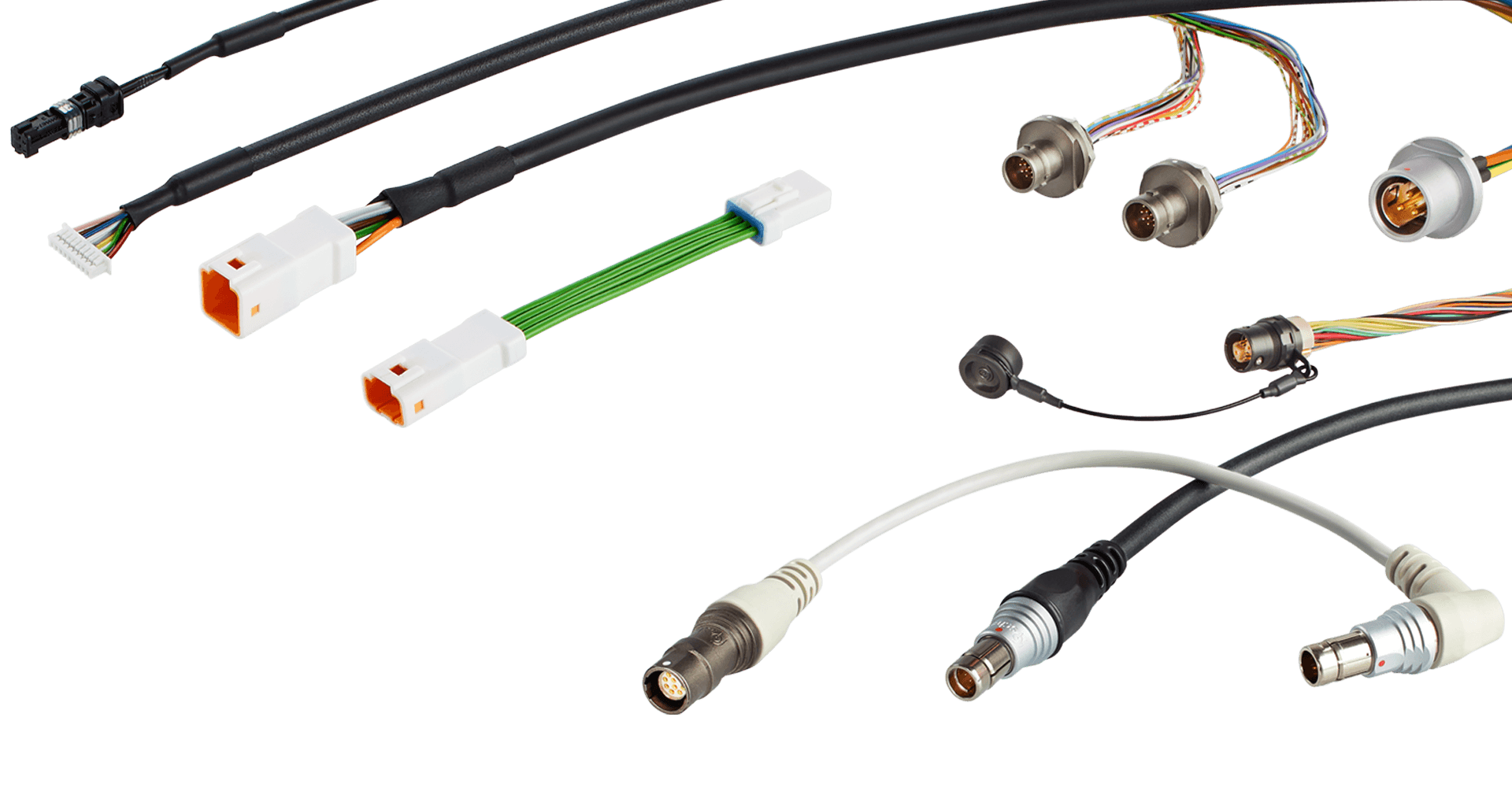

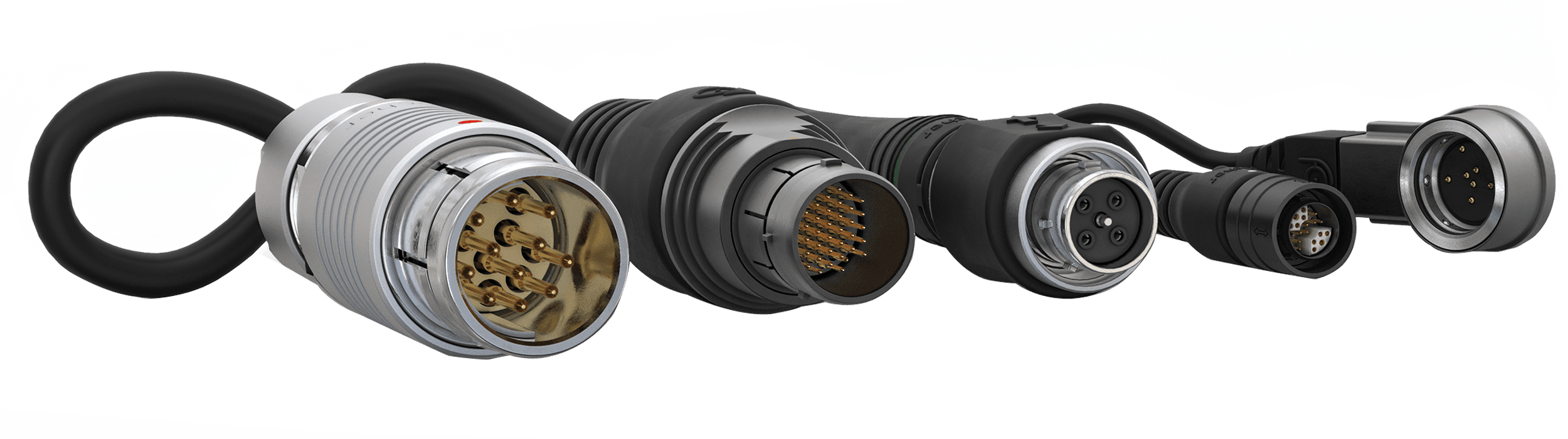

The right solution for every application

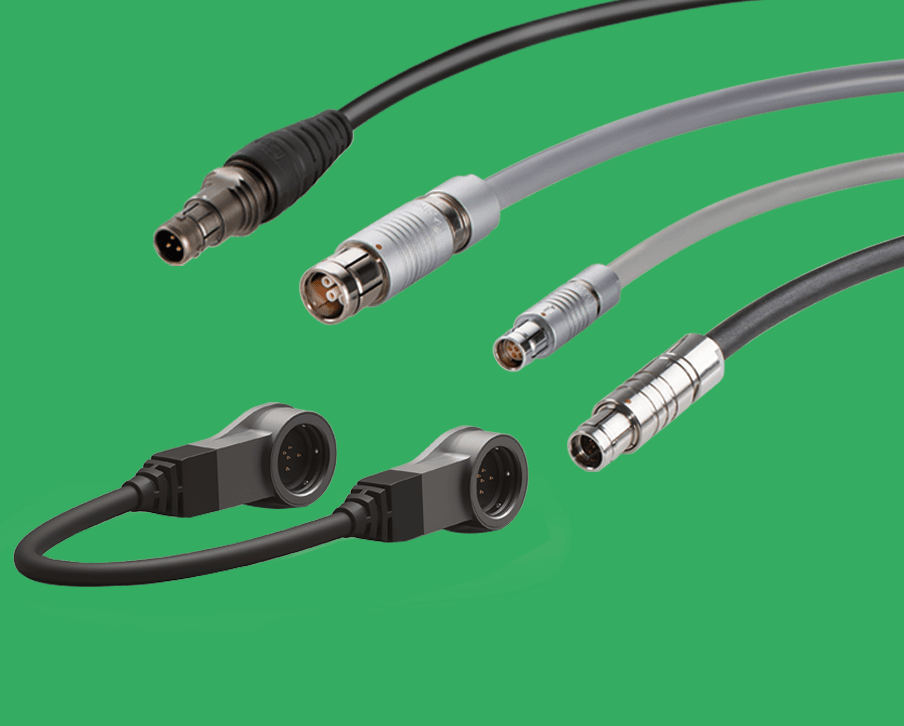

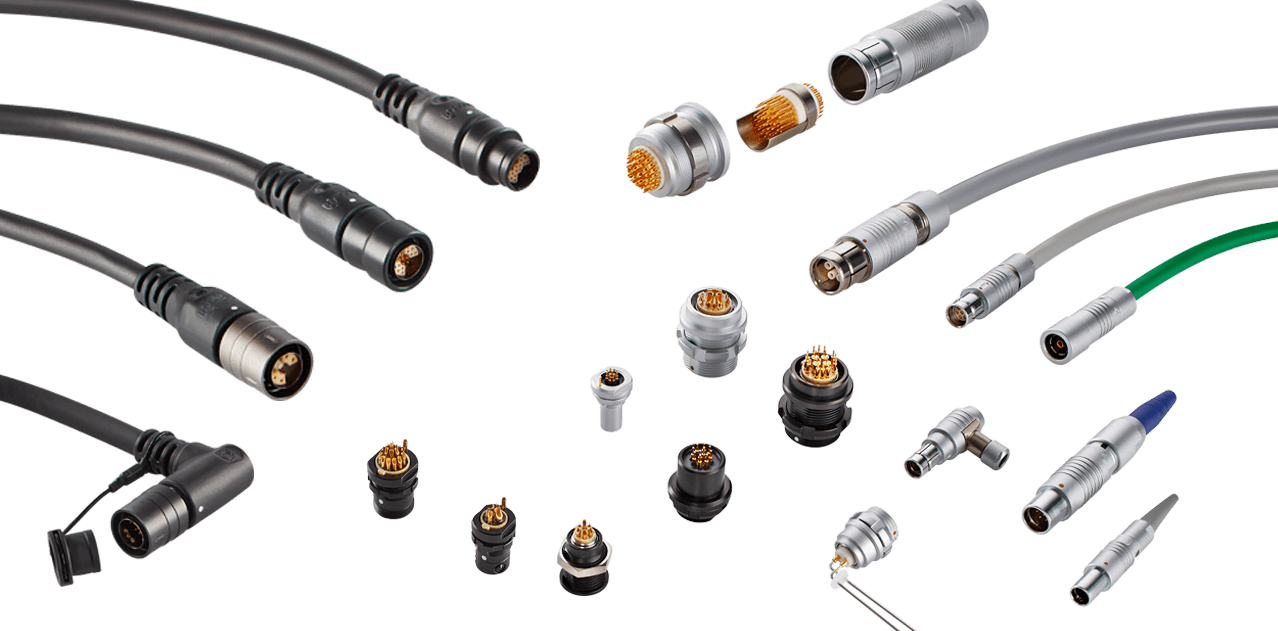

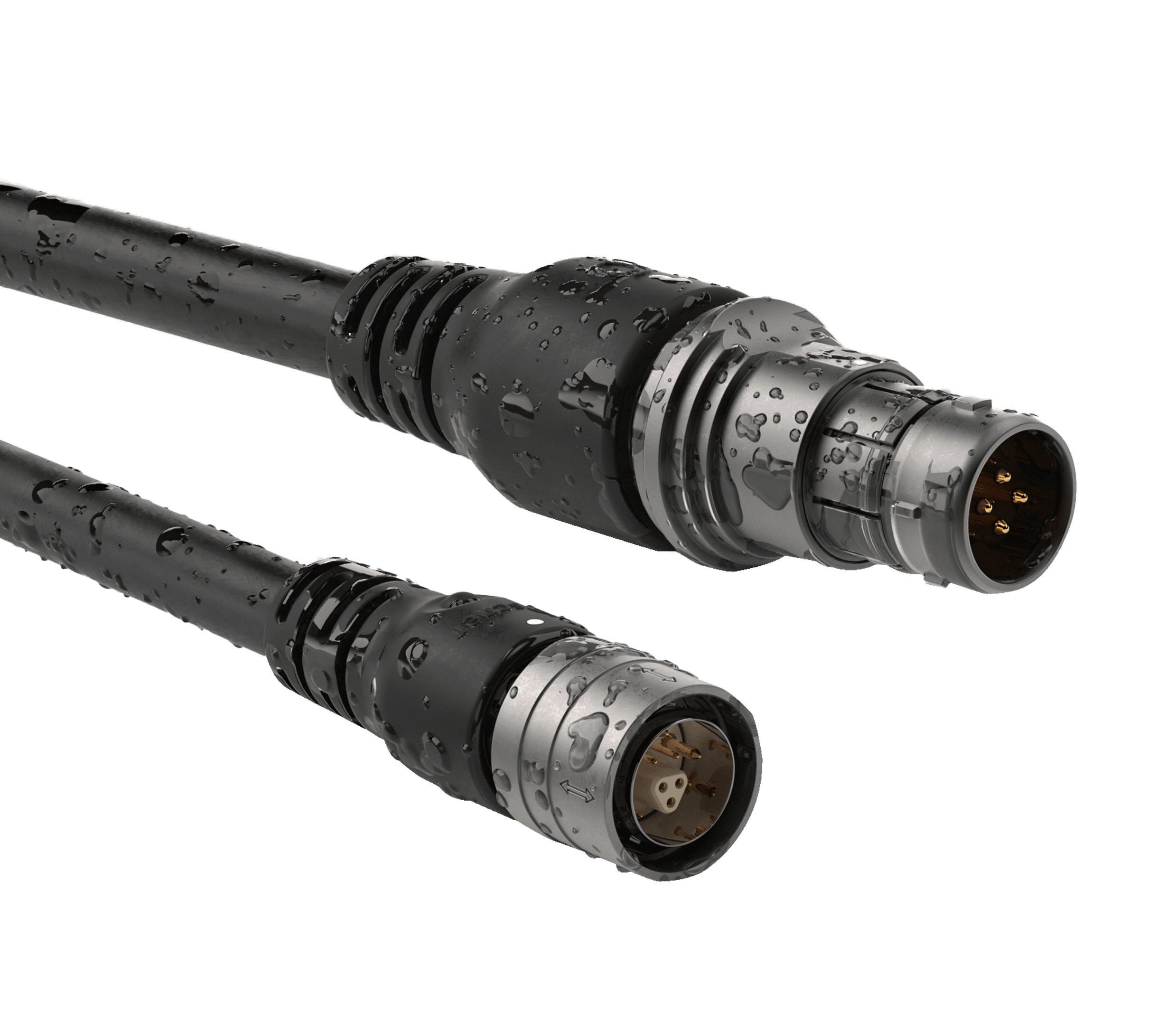

For industrial applications, but especially for very demanding or extreme environments, we offer an extensive range of connector solutions for all wiring configurations (board to wire, panel to wire and wire to wire). For example, watertight or hermetically sealed connectors, connectors for use under water or hybrid versions with all functions (current, signals, air, liquid, etc.) in one connector. Equipped with extremely reliable contacts, suitable for more than 5,000 mating cycles and with secure and reliable push-pull mating.

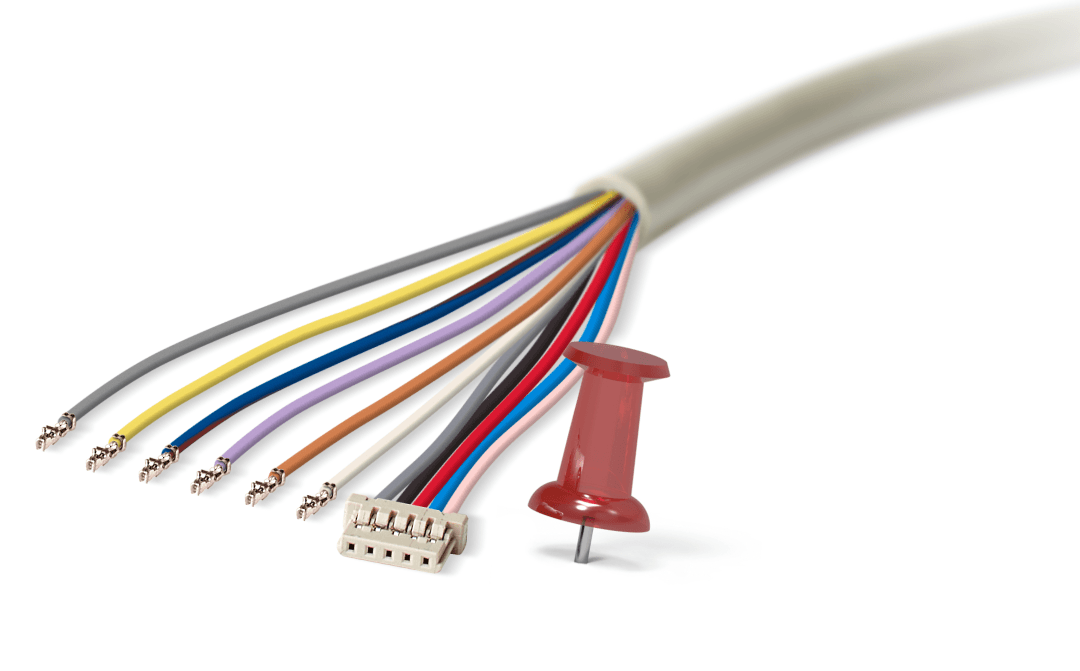

Small contacts and fine pitches

Even thin wires with a flexible core of AWG 30 (0.05 mm2) are cut to length, stripped and fitted with small crimp contacts on fully automatic wire processing machines. In the same cycle the quality of each crimped contact is automatically tested. Pitches of 1 mm or less make very compact and reliable wiring design possible, using crimp contacts for discrete wires or ribbon cable and connectors for Flat Foil Cable (FFC).

Waterproof connectors

Waterproof connectors are designed for use in wet or submerged environments to ensure secure and reliable connections without any leakage into or out of the equipment. Sealing is a complex science, involving physical aspects such as mechanical design, materials & surface sciene and fluid behavior. Whether your devices and installations are exposed to rain, mud, intense water jets, salty mist or deep-sea immersion, it’s crucial to have sealed connectivity solutions to maintain their long-term reliability. We assist and guide you in carefully selecting solutions with the appropriate level of environmental and hermatic sealing for your specific device and operating conditions.

We are most happy to assist you in this design process

with samples and suggestions.